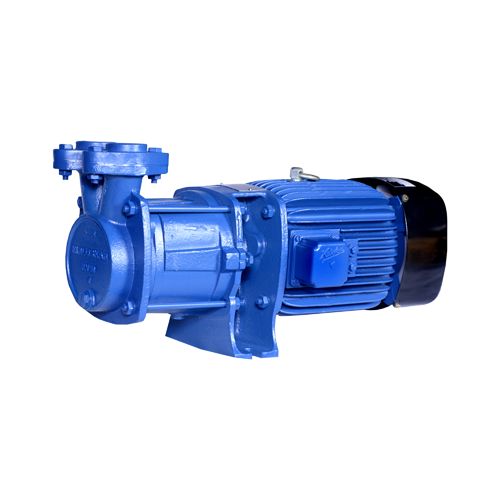

VACUUM PUMP – KV

KBL’s exclusive range of KV/DV vacuum pumps are majorly used for priming of large pumps. As the name suggests, these are also used to create a ‘vacuum’ by enabling evacuation of air and thus are widely used for applications like drying, evaporation, degasification, condensation, etc.

- Priming of Large Pumps

- Evacuation of Air from Suction Pipes and Chambers

- Twist Drilling Machine, Removing Water from Pulp Layer, Labelling, Bottle Filling, De-odorising, etc.

- Drying, Evaporation, Distillation, Filtration, Sterilisation, Condensation, Degasification, Sucking Gases, etc.

- Extrusion Machines

PRIMARY USAGE

APPLICATIONS

KBL’s exclusive range of KV/DV vacuum pumps are majorly used for priming of large pumps. As the name suggests, these are also used to create a ‘vacuum’ by enabling evacuation of air and thus are widely used for applications like drying, evaporation, degasification, condensation, etc.

- Priming of Large Pumps

- Evacuation of Air from Suction Pipes and Chambers

- Twist Drilling Machine, Removing Water from Pulp Layer, Labelling, Bottle Filling, De-odorising, etc.

- Drying, Evaporation, Distillation, Filtration, Sterilisation, Condensation, Degasification, Sucking Gases, etc.

- Extrusion Machines

SPECIFICATIONS

- Vacuum: Up to 600 mm of mercury

- Air Flow Rate: Up to 55 m/hr (at mean sea level)

- Power Ratings: 0.75 to 2.2 kW (1 to 3 HP)

- Voltage Range: 180 to 240 volts (single phase) 300 to 440 volts (three phase)

- Insulation: B class

- Protection: IP 44

MATERIAL OF CONSTRUCTION

- Rotor (Impeller) : Stainless Steel

- Delivery Casing : Cast Iron

- Motor Body : Cast Iron

- Pump Shaft : Carbon Steel

FEATURES

- Wide Voltage Design

- Designed to Prevent Overloading

- Replaceable Wearing Parts

- Dynamically Balanced Rotating Parts

DOWNLOADS

-

VACUUM PUMP – KV

- Buy Now

-

Max Head:

Upto 600m -

Max Capacity:

Upto 55 m/h

Product Description

KBL’s exclusive range of KV/DV vacuum pumps are majorly used for priming of large pumps. As the name suggests, these are also used to create a ‘vacuum’ by enabling evacuation of air and thus are widely used for applications like drying, evaporation, degasification, condensation, etc.

- Priming of Large Pumps

- Evacuation of Air from Suction Pipes and Chambers

- Twist Drilling Machine, Removing Water from Pulp Layer, Labelling, Bottle Filling, De-odorising, etc.

- Drying, Evaporation, Distillation, Filtration, Sterilisation, Condensation, Degasification, Sucking Gases, etc.

- Extrusion Machines

Product Details

SPECIFICATIONS

- Vacuum: Up to 600 mm of mercury

- Air Flow Rate: Up to 55 m/hr (at mean sea level)

- Power Ratings: 0.75 to 2.2 kW (1 to 3 HP)

- Voltage Range: 180 to 240 volts (single phase) 300 to 440 volts (three phase)

- Insulation: B class

- Protection: IP 44

MATERIAL OF CONSTRUCTION

- Rotor (Impeller) : Stainless Steel

- Delivery Casing : Cast Iron

- Motor Body : Cast Iron

- Pump Shaft : Carbon Steel