KIRLOSKAR BROTHERS LIMITED

Established 1888 A Kirloskar Group Company

This is an integral component of the value of our business. Improving the enabling environment for business and strengthening the value chain bears a testimony to the value we place in development activities, while we also partner in their growth story.

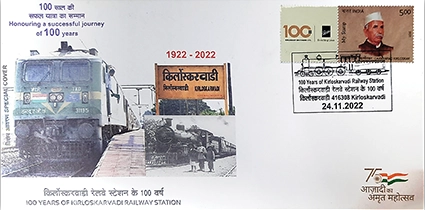

In 1910, when Shri Laxmanrao Kirloskar was establishing the 36-acre Kirloskarvadi plant, he chose a location with a railway station in its vicinity, the Kirloskarvadi Railway Station (earlier known as Kundal Road Station). Stalwarts and patriots like Pandit Jawaharlal Nehru, V Shantaram, Baburao Painter, Dada Saheb Phalke, Bharat Ratna awardee Dhondo Keshav Karve and Dr. Sarvapalli Radhakrishnan travelled to Kirloskarvadi railway station.

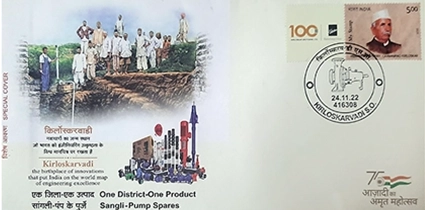

The station completed 100 years of existence in 2022. India Post also released a first-of-its-kind unique pictorial stamp with a KBL pump picture, and two special covers. The first cover commemorated 100 Years of the railway station, while the second honoured Kirloskarvadi’s contribution under ‘One District One Product’ scheme.

Once a barren land, the Kirloskarvadi plant has played a critical role in KBL’s journey and in carrying forward Shri Laxmanrao Kirloskar’s dream of making India AtmaNirbhar. It has come a long way from ploughs to pumps for critical applications in nuclear power plants and witnessed several key milestones. These products are used by Millions of farmers and households and across industries, including critical sectors like nuclear plants and defence. Several iconic structures in India and globally are using these products. The Atal Tunnel, Statue of Unity, Burj-Al-Arab and the Shard are some of these monumental buildings.

We believe in building long-term, transparent, and trust-based relationship with partners, while adhering to applicable norms and corporate ethics. We are also building the capabilities of our partners and also engaged in knowledge-sharing with them.

The key objective of our optimally managed supply chain is to improve the organisational performance and customer satisfaction by improving product and service delivery to the customer. We also integrate environment performance considerations in the procurement process including planning, use and disposal, environmental aspects, potential impacts, and costs associated with the Life-Cycle Assessment, to have a minimal negative impact on the environment.

We are committed to reducing resource consumption and minimise waste, while considering life-cycle costs of products, as we reduce, reuse, and recycle resources through the procurement activity. We prefer to buy recycled and partly recycled products to optimise consumption and stimulate demand for recycled products, promote collection and reprocessing of waste and work towards zero discharge to the landfill.

Through our supply chain, we explore new avenues of ensuring best procurement practices and a healthy partnership approach with all our business partners. This approach helps in developing a more sustainable supply chain and helps in cost reduction, managing risks better, generating new revenue sources and boosting our brand value.

To develop a more sustainable supply chain

To aim at cost reduction, managing risks better, generating new sources of revenue, boosting the brand value

Steps taken for Sustainable Packaging

Use of recyclable materials at plants

Switching to materials complying with ROHS standards

New packaging complying with ISPM-15

Commitment and acceptance to supplier Code of Conduct is ensured from all suppliers during the Supplier Registration Process:

Gaining sustainable benefits through Channel Partners/Suppliers

Customer care is always our priority, and we are always seeking faster and convenient ways to reach and serve our customers. We serve them through a dedicated and extensive network of authorised service and spares dealers and service centres.

Some key features of how we provide enhanced customer service:

Customer Safety & Privacy

We provide Operations & Maintenance training to customers to avoid operational failures in the project. Structured customer trainings are also conducted at plants and on the site. Customer data such as population, prices and complaints are maintained in CRM and SAP HANA in a secured manner. We also arrange Sampark Programs and Customer Satisfaction Surveys to address product and service-related issues.

Customer Satisfaction Survey

Our customer satisfaction survey is aimed at evaluating and measuring satisfaction of customers and channel partners across business verticals

KBL has a large set of dealers committed for generations. Our channel sales philosophy is to ensure that the interest of both KBL and its dealers is taken care of. As a part of our business excellence model and for ultimate customer delight, we continuously work towards building a strong and mutually beneficial relationship with our Channel Partners.

Our Key Dealer Engagement Activities

Annual dealer conference at corporate office, Yamuna

© 2023 Kirloskar Brothers Limited (India) | All Rights Reserved.