INTELLECTUAL CAPITAL

Over the past decade, we have made strategic investments in various digital initiatives, which have yielded benefits by providing technological advantages and additional revenue streams in the services business. Some of these initiatives include Virtual Reality (VR), Augmented Reality (AR), Artificial Intelligence (AI), Internet of Things (IoT) and 3-D printing.

Strategies Impacted

S1 S2 S3 S4

S5 S6 S7

SDGs Impacted

Material Issues Impacted

- Economic performance

- Talent attraction and retention

- Supply chain management

- Customer safety and product quality

- Cyber security and digitisation

- Market presence

- Product stewardship and innovation

KEY HIGHLIGHTS

21

Total patents granted

03

Patents granted in FY 2023-24

100+

Research papers filed

₹ 290 mn

Investments in R&D

01

Patent filed in FY 2023-24

03

Research papers published

14%

Contribution of new product sales

227

New products launched

162

Number of R&D employees

RECEIVED PATENTS FOR:

- Inline water purification by investing in a system for online purification with pump, while supplying water

- Shaft sealing mechanism for triple offset butterfly valve

- Hydro power generation system

OUR INNOVATIVE SOLUTIONS

- KirloSmartTM Condition Monitoring next generation

- Special Pumps for nuclear applications

- Solar Pumping System

- Pump/Valve Selection Package

- Fire Pump Monitoring system

- Lowest Lifecycle Cost (LLCTM) Pumps

- Augmented Reality Mobile Training

- Canned Motor Pump for industry, marine and defence ships

- Additive manufacturing 3D Printer

- Large 7.5 MW Vertical turbine pump

- FM/UL Fire Package with Auto-prime Unit

- Dry pit submersible pump NS600/64XDG can work as dry pit as well as wet pit

- Development of products towards import substitution

- KBL’s Largest Turbine Inlet Valve of 3800 mm PN2.5 with Dual Ground Mounted Cylinder arrangement

- Commissioned 16 MW metallic volute pump with discharge guide vane

- Hydroturbines for Peruvannamuzhy (2 x 3000 kW) HEP and Pazhassi Sagar (3 x 2500 kW) HEP

- Monobloc pumps and Self Priming pump sets with IE4/IE5 Ultra premium efficiency motors

- 150 mm oil-filled submersible pump set

- Lifter pump series for domestic application

- 75 mm KS3 PURNA submersible pumps

- Wide voltage KAM series pumps

TECHNOLOGY TO TACKLE CUSTOMERS SUSTAINABILITY CHALLENGES

Customer Priorities

- Energy efficiency

- Lower downtimes and maintenance costs

- Safety and maintenance

Technology Opportunities

- High-efficient hydraulics and ultra-premium efficient motors

- Remote multiple pump monitoring and diagnostics tool

- Innovative design for energy efficiency, safety and maintenance ease

We are leveraging our technological and domain expertise:

- To create a scalable and sustainable business through the subscription platform -

- Proprietary innovative solutions

- Remote failure prediction analytics, troubleshooting and monitoring

- No periodic site visits required

- Higher uptime, lower catastrophic failures and spare part inventory carrying costs to customer

- Highly scalable with less manpower requirement

- To lower turnaround time by taking efforts for Bill of Material automation

- To improve time-to-market by establishing a new dedicated R&D test lab to handle upcoming product development

- Digital Transformation of Projects

Bidding

- Pump selection software Dolphin for marketing executives

Engineering and Design

- 2D/3D digitisation of drawings, Windchill-data management of critical processes

- Auto generation of baseplate drawings based on linkage between Excel and CREO software, minimising manual intervention

- Development of various design sheets for swift calculations

Procurement

- Implemented through SAP Hana, Windchill-data management

LEADING DIGITAL TRANSFORMATION IN THE PUMPS INDUSTRY

STAYING AHEAD OF THE CURVE THROUGH DIGITAL INITIATIVES

3D Printing

- World’s largest 3-D printer for foundries installed in 2013 at Kirloskarvadi plant

- Contributes significantly towards faster turnaround for standard and engineered moulds for castings used in domestic and export applications

- Flexible and universal as it supports replacement business in pumps

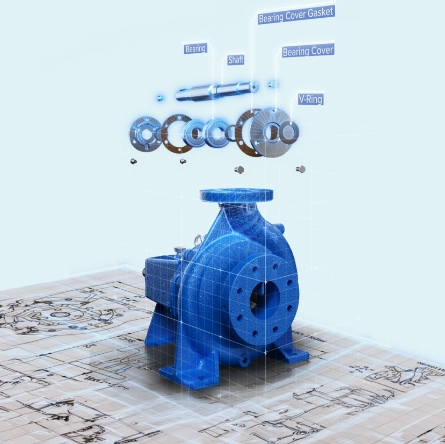

Augmented Reality/ Virtual Reality

- Used for training employees and customers

- Consistent service delivery by documenting knowledge of service engineers for a decade and ensuring this knowledge is our IP

Artificial Intelligence

- Use of Dolphin, a system that provides a proprietary machine learning algorithm

- Analysis automation based on historical and live data with higher uptime and lowered catastrophic failure for customers

IoT

- Remote multiple pump monitoring and diagnostics tool that is accessible through smartphones and computers

- IoT-enabled manufacturing across domestic plants

- KirloSmartTM Fire is a remote monitoring solution for fire pumping system (Engine pump set and motor pump set)

RESEARCH & DEVELOPMENT STRATEGY

SHAPING A NEW ERA IN TECHNOLOGY

We were awarded a patent for the Hydro-Power Generation System for PICO pump turbine, which underscores our steadfast commitment to innovative energy solutions and technological advancement. The salient features of the PICO hydro system include cost efficiency, enhanced mobility due to portability, minimal maintenance pre-requisites and a user-friendly compact design that simplifies installation.

We have also been granted patents for innovating a one-of-its-kind Shaft Sealing Mechanism for Triple Offset Butterfly Valve and System & Method for In Line Water Purification.

We continued to stay ahead of the curve by making investments in virtual reality, augmented reality, artificial intelligence and 3D printing, which has served to maintain our technological lead and create additional revenue streams in the services business. The use of artificial intelligence and self-learning systems for our sales teams and end users enabled selection, customisation and performance of application engineering around existing products. Simultaneously, augmented reality facilitated hands-on service and improved customer response.

We own the world’s largest 3D printer at Kirloskarvadi plant for faster turnaround of moulds in foundries. We are addressing on minimising carbon footprint and supporting green gas emission process by additional focus on special DBxe series in stainless steel material and hydro turbines.

INNOVATIVE ENERGY SOLUTIONS AND TECH ADVANCEMENT

An Unwavering Dedication

- Our innovative KW-LC and KW-SC pumps have enabled our entry into the rapidly expanding HVAC market

- Suitable for a wide range of applications such as water supply, HVAC, hot water, drinking water and cooling water applications

- Addressing range extension of GKW and new series DBxe has introduced range efficiency and compliance with MEI 0.7 norms

- Readiness of FM / UL certified Products CD15K -MSMO (Multi-Stage Multi-Outlet) TQ20B, BT10D (Horizontal split case, Vertical Turbine Pumps with UL certification)

- Refining existing range of multistage RKBx pumps

- Introduction of innovative products such as High-Performance Butterfly Valve, Centric Butterfly Valve, Floating Ball Valve has addressed product gaps for different applications and made additions to the product basket, thereby improving market penetration

- Developed New Economical and Environmentally Sustainable range of “Series-E Butterfly Valve (Double/Single Eccentric)

New R&D Facility In Kirloskarvadi Plant

NEW R&D TEST LAB

- Captures all parameters with one-click

- Accurate and error-free power measurement

- Flexibility to select flow meter size

- No manual interference or human error

NEW COLLABORATIONS FOR R&D

- SICcast Germany for Flue Gas Desulfurisation slurry pump coating application

- IMPSA Argentina for mid to large hydroturbines

COLLABORATION INSTITUTIONS

- Hydraulic Institute (HI) Bureau of Indian Standards (BIS)

- International Organisation for Standardisation (ISO)

- FM (Factory Mutual) and UL (Underwriters Laboratories)

- Indian Institute of Technology (IIT) Madras

- Indian Institute of Technology (IIT) Powai

- Indian Institute of Science (IISc) Bengaluru

- National Institute of Technology Karnataka (NITK) Surathkal

- Veermata Jijabai Technological Institute (VJTI) Mumbai

- RIT College of Engineering for Online Monitoring of Domestic Pumps

PEOPLE, COMPETENCIES AND SYSTEMS

- We have an enriched knowledge management system. It gives priority for preserving, nurturing, developing and harnessing both people knowledge and process knowledge

- The value of employee knowledge, skills, business training and proprietary information provides a competitive advantage for the Company. R&D team has a good mix of experienced and young engineers well trained and skilled in handling product development with excellent skills to handle modern numerical tools

- A focussed process-centric approach adapted by us helps the R&D teams to document the processes and ensure predictable results in all domains

- Our R&D team currently focusses on expanding its skills in Material science, IoT solutions and large hydro turbines in addition to several pump product developments for industrial and special applications

HIGH EFFICIENCY SUBMERSIBLE MODELS

- Released 29 models of 150 mm submersible pump series with high efficiency (5 star and 4 star - KS6 150, 240 & 260). This will help to increase the business from institutional orders

- Total 379 submersible models are now BEE star rated. Our focus is on increasing the 5 star and 4 star rated models. We have plans to add new 81 BEE models in 2024-25