We remain committed to promoting sustainable development by integrating economic, environmental and social considerations into our key business imperatives. With a strong focus on minimising our ecological footprint, we remain dedicated to implementing strategies that contribute to a low-carbon future and positive environmental impact, maintaining a strong focus on minimising our ecological footprint.

M1Product stewardship and innovation

M2Emissions management

M6Energy management

M7Materials

M9Supply chain management

M20Biodiversity

M21Waste management

M22Water and effluents management

Renewable Energy added

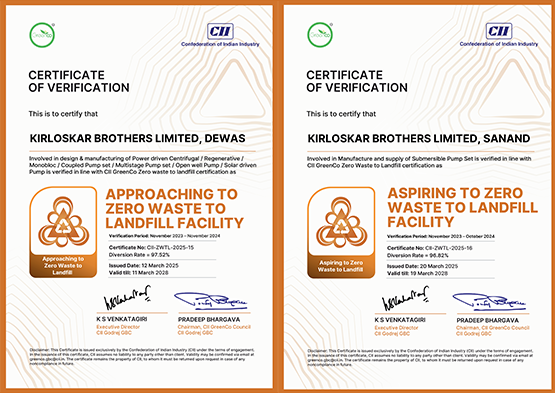

awarded as “Approaching to Zero Waste to Landfill” by CII

awarded as “Aspiring to Zero Waste to Landfill” by CII

CII GreenPro Ecolabel certified products

Water recycled

GreenCo certified manufacturing plants

Enhanced energy performance of Borewell Submersible Pumps with

Reduction in Scope 1 emissions

At KBL, we strongly believe in joining forces with multiple stakeholders to promote the culture of sustainability across the organisation. By combating climate change and managing natural capital responsibly, we continue to create a lasting impact on the environment and contribute to a more sustainable future for our next generations.

Our approach to sustainability is centred around executing environmental stewardship initiatives to minimise our operational impact on biodiversity, natural resources and air quality.

In a significant step towards sustainability, the Company signed a Solar Open Access Power Purchase Agreement (PPA) to power the manufacturing facilities at Kirloskarvadi and Kolhapur. The 13.5 MWp solar project will generate ~20 Million units of clean energy annually. This will help in substantially increasing the renewable energy usage at Kirloskarvadi plant from the existing 25% to 75%.

On the other hand, the renewable energy usage of The Kolhapur Steel Limited (TKSL), a subsidiary company of KBL, will also increase to 75%.

This will lead to a significant reduction in KBL’s carbon footprint by offsetting 14,200 metric tonnes of CO2eq emissions yearly.

PICO and PAT, patented pump models of KBL, are designed for meeting the smaller energy requirements in diverse industries. These pumps can be operated in reverse as a turbine for generating electricity. While PICO is generally used for meeting energy requirements of up to 5 kW, PAT is used for meeting comparatively higher energy requirements of up to 100 kW. Installed as a full-fledged energy generation unit, these solutions are not only helping companies reduce their energy costs, they are also considered a potent alternative for combating global warming.

The KW-SC pump is a ground-breaking addition to KBL’s vertical inline pump series. Designed for circulation of liquids for heating and air-conditioning systems, the versatile pump enhances HVAC operations and temperature control and potentially reduces energy consumption and costs. Its compact vertical design fits into a limited space, making it ideal for crowded mechanical rooms. The pump is suitable for air conditioning, bottling plants, industrial circulation and water boosting systems. Some of the key benefits offered by the pump are – easy maintenance, minimising downtime and costs.

KBL’s Lowest Lifecycle Cost (LLCTM) Pump series focuses on reduction in energy consumption and maintenance cost. Due to their unique features, these lowest lifecycle cost pumps offer significant energy savings potential during their lifespan, without majorly reducing pump efficiency over a longer period and hence, this results in low life cycle cost in comparison with conventional pumps. These pumps are expected to reduce 1,000-1,200 MT CO2eq within the first 10 years of installation.

The highly efficient end-suction pump series (DBxe) can save up to 20 MT CO2eq in the first 10 years of installation operations. With thousands of such pumps being installed every year, this is expected to result in cost savings and reduced energy consumption on an aggregate basis.

The Company offers efficient, reliable and sustainable water pumping solutions using solar energy. These solutions reduce reliance on fossil fuels and are ideal for agriculture, residential bungalows, farmhouse, multi-story residential complexes and commercial uses. Kirloskar Solar Pump and Jalverter® technology make optimum use of solar energy to deliver water at virtually zero electricity and low maintenance cost.

The Company understands social, economic and environmental value of water and the need to conserve and resue it. It promotes sustainable and equitable use of water to address the growing scarcity and to scale a positive impact on nature and water.

KBL recognises that climate change is a significant threat to our planet and requires immediate actions.

KBL Scope 3 emission profile FY 2024-25 (Category-wise %)

The Company values environmental resources and acknowledges the concept of circular economy, which improves business efficiencies and reduces primary resource consumption and waste generation.

KBL is dedicated towards environmental sustainability and acknowledges that biodiversity is essential for the processes that support life on Earth. The Company has adopted various initiatives to improve the green belt within and beyond the fence.