-

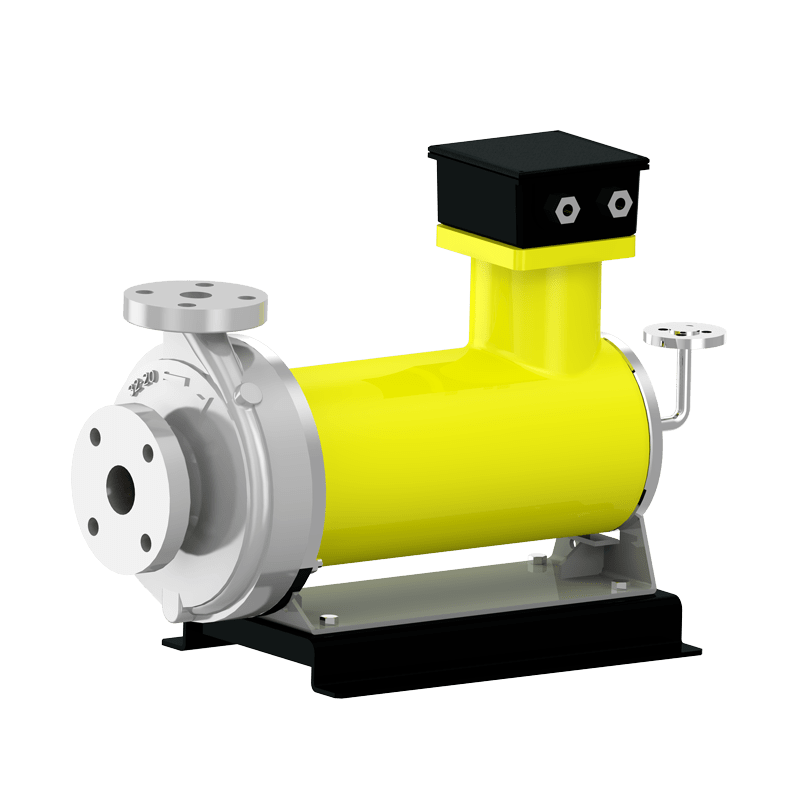

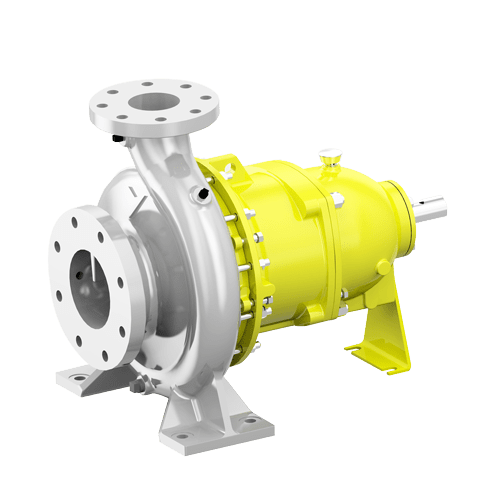

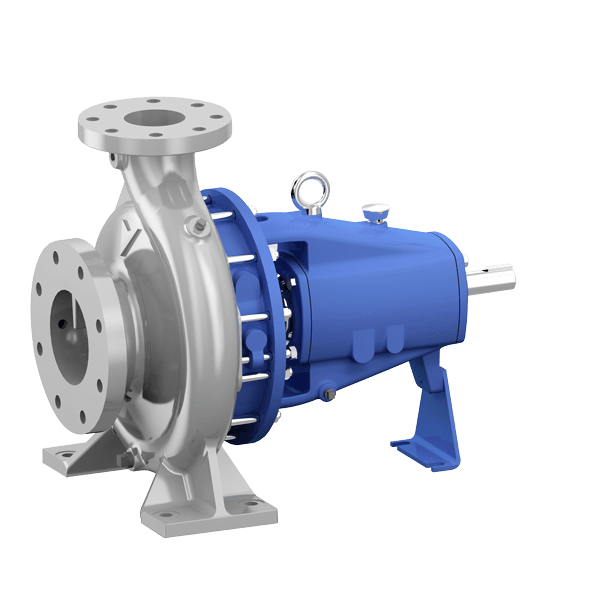

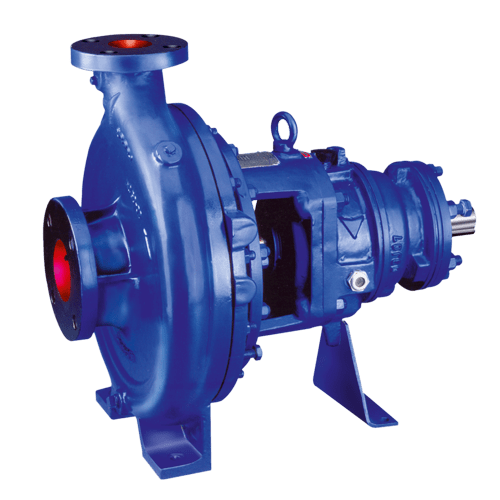

End Suction Process Pump - i-CP

-

-

Max Head:

Upto 85 m -

Max Capacity:

Upto 2900 m3/hr

-

- Enquire Now

Product Description

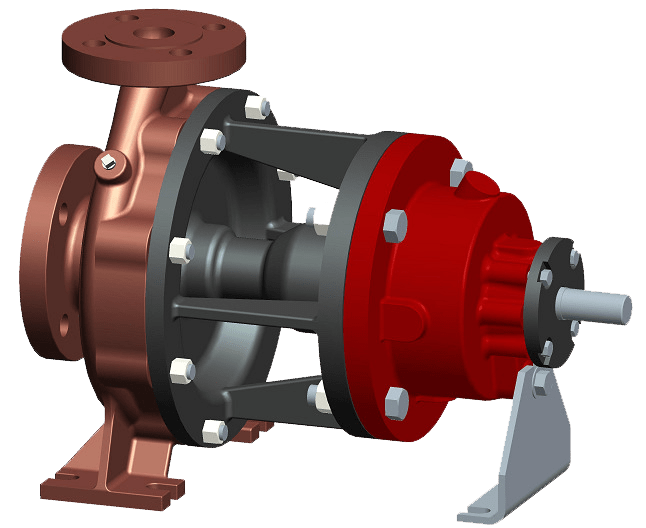

Kirloskar End Section Process Pump i-CP pumps are horizontal, radially split, single stage, centrifugal end-suction volute with top centerline delivery. The impeller is of an enclosed type. The bearing housing is fitted with a support foot. The pump shaft is supported by pre-lubricated anti-friction sealed bearings as a standard scope of supply. i-CP pumps come without mechanical seal & without gland packing arrangement and yet ensure zero leakage from the stuffing box. This feature is achieved by the innovative design of the shaft sleeve, expeller and fluid arrester.

Product Details

Applications

- Light chemicals like caustic soda, weak acids, etc.

- Food & beverage industries – (sugar, vegetable oils, etc.)

- Other applications like hot water, brine, DM water, lime water, etc.

Specifications

- At 1450 rpm

- Rate of flow up to 180 m3/hr

- Head up to 55 m

- At 2900 rpm

- Rate of flow up to 150 m3/hr

- Head up to 85 m

- Temperature – up to 95 °C

Features

- Environment-friendly zero leakage pump.

- Highly energy efficient

- Maintenance free

- Pump without a mechanical seal & without gland packing arrangement

- No periodic bearing lubrication required

- Sealing/flushing water not required

- Self-venting design

- Pump with back pull out design

- Conforming to ISO 2858 standard

- Compact design

- Sturdy yet light in weight

- Shaft is fully protected from liquid

- Wide interchangeability of components

End Suction Process Pump - i-CP

Product Overview

Kirloskar End Section Process Pump i-CP pumps are horizontal, radially split, single stage, centrifugal end-suction volute with top centerline delivery. The impeller is of an enclosed type. The bearing housing is fitted with a support foot. The pump shaft is supported by pre-lubricated anti-friction sealed bearings as a standard scope of supply. i-CP pumps come without mechanical seal & without gland packing arrangement and yet ensure zero leakage from the stuffing box. This feature is achieved by the innovative design of the shaft sleeve, expeller and fluid arrester.

PRIMARY USAGE

- Light chemicals like caustic soda, weak acids, etc.

- Food & beverage industries – (sugar, vegetable oils, etc.)

- Other applications like hot water, brine, DM water, lime water, etc.

- At 1450 rpm

- Rate of flow up to 180 m3/hr

- Head up to 55 m

- At 2900 rpm

- Rate of flow up to 150 m3/hr

- Head up to 85 m

- Temperature – up to 95 °C

- Environment-friendly zero leakage pump.

- Highly energy efficient

- Maintenance free

- Pump without a mechanical seal & without gland packing arrangement

- No periodic bearing lubrication required

- Sealing/flushing water not required

- Self-venting design

- Pump with back pull out design

- Conforming to ISO 2858 standard

- Compact design

- Sturdy yet light in weight

- Shaft is fully protected from liquid

- Wide interchangeability of components