Capabilities

Our innovative and trademark products and solutions are the result of the relentless efforts and expertise of our talented engineering team. These advanced capabilities reflect the progressive mindset and technical excellence of our passionate engineers.

Driven by a deep understanding of customer and market needs, our engineers consistently develop superior and innovative solutions, backed by years of experience and specialised technical knowledge.

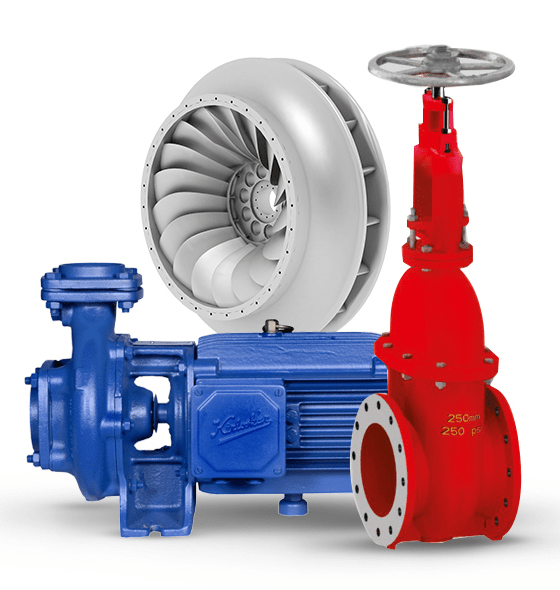

Design & Development of Pumps, Hydro Turbines, Valves and Special Pumps

- Advanced Pump Design:

– Centrifugal and vertical turbine pumps designed in compliance with national and international standards

– Utilisation of advanced CAD tools, including Computational Fluid Dynamics (CFD), Inverse Design, and Finite Element Analysis (FEA) - Efficiency Optimisation:

– Pump efficiency enhanced through impeller blade optimisation using Inverse Design software - Lowest Life-Cycle Cost (LLC) Pumps:

– Designed to minimise operational and maintenance costs while maximising Mean Time Between Failures (MTBF) - Specialised Applications:

– Pumps for nuclear applications, including primary and secondary cycle systems, and canned motor pumps

– Circulating water pumps and condensate extraction pumps for power generation applications

Design of Hydro Turbines

Our engineering expertise spans the design and development of a wide range of hydro turbines, including:

- Francis, Kaplan, and Pelton turbines, in both horizontal and vertical orientations

- Pump as Turbine (PAT) systems for micro-hydro applications, ranging from 5 kW to 100 kW

- Cross-flow turbines specifically designed for micro-hydro installations

CFD Study of Pumps, Turbines and Valves

We utilize Computational Fluid Dynamics (CFD) to enhance design accuracy and performance:

- Design verification through CFD analysis helps improve flow patterns and predict pump efficiency, which is validated against experimental results

- Net Positive Suction Head Required (NPSHR) for centrifugal pumps is also accurately predicted using CFD studies

Multi-Phase Flow Analysis

We leverage advanced CFD techniques to analyse complex multi-phase flow scenarios, enabling accurate prediction and optimisation:

- Cavitation Prediction – Identification of cavitation zones within pumps to enhance reliability and performance

- Particle Tracking – Monitoring of suspended particles in liquid flow for wear analysis and system efficiency

- Sump Air Entrainment & Silt Formation – CFD-based prediction of air entrainment and sediment accumulation in pump intake systems

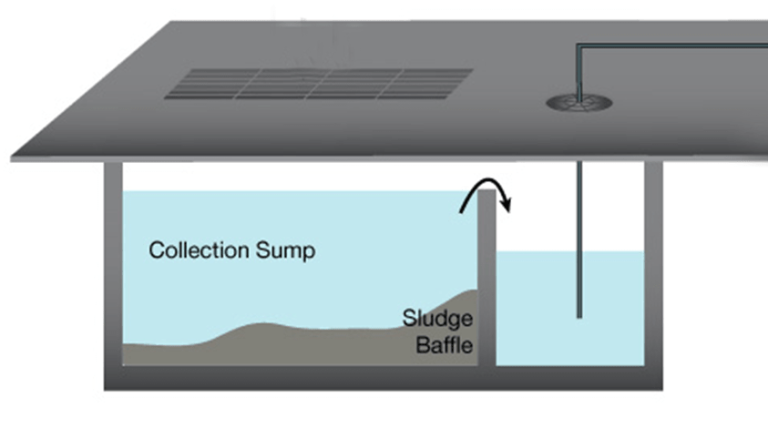

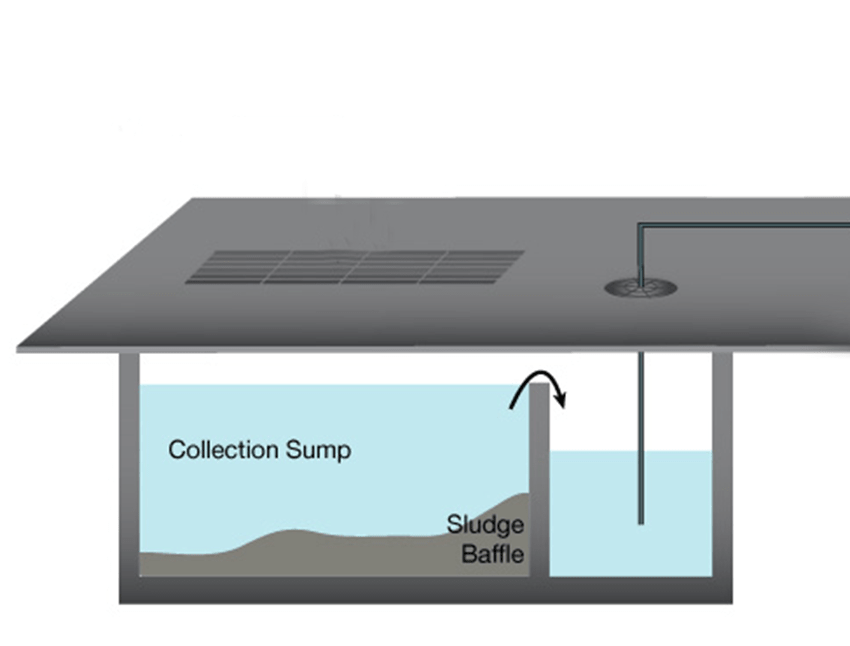

CFD Sump Study

Our sump designs are based on ANSI/HI standards and validated using CFD analysis to:

- Detect vortex formation and air entrainment

- Minimise swirl angle at the pump inlet

- Optimise sump geometry for improved hydraulic performance

This approach significantly reduces design time and cost, with results validated against experimental data.

Physical Sump Model Study

Scaled-down physical models of sump structures are tested at our facility to:

- Identify vortex formation and swirl angles

- Optimise flow characteristics by modifying intake geometry

- Validate CFD findings and ensure real-world performance

Finite Element (FE) Analysis

We perform comprehensive FE analysis to ensure structural integrity and performance across a wide range of components, including pumps, valves, hydro turbines, and associated systems. Our capabilities include

- Static Analysis

- Dynamic Analysis

- Seismic Analysis

- Shock and Fatigue Analysis

- Thermal Analysis

- Coupled-Field Analysis

These simulations help us validate designs under various operating conditions and ensure compliance with international standards.

Surge Analysis of Transmission Mains

To protect pump discharge mains from surge pressures caused by sudden pump stoppage or power failure, we conduct detailed surge analysis. The system is evaluated and safeguarded using appropriate surge protection devices such as:

- Air Vessels

- Surge Tanks

- Air Valves

We identify optimal locations for these devices within the discharge mains to ensure maximum protection and system reliability.