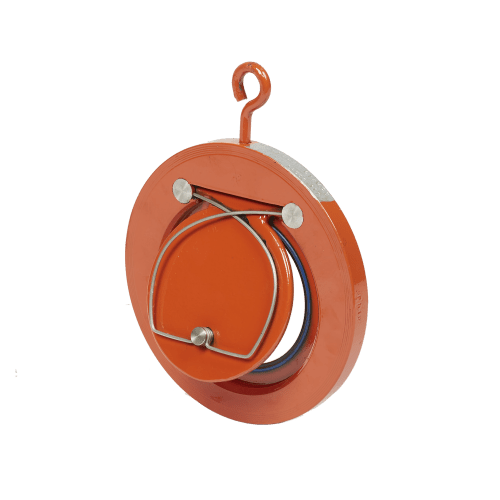

Forged Steel Check Valve

- Enquire Now

Product Description

Kirloskar Forged steel FS check valves, widely used by the National Thermal Power Corporation, Nuclear Power Corporation, industrial users and refineries, are designed and manufactured as per BSEN ISO: 15761/ BSEN: 12266-1/ BS 5352 and tested as per BSEN: 12266-1/API -598/BS-5146 standards.

Kirloskar FS check valves are designed for handling very high pressures. Its rigid and sturdy design along with its low pressure characteristicsmake it a very formidable model in the entire product line.

Product Details

Applications

- Refineries and petrochemical industries

- Fertiliser plants

- Thermal power plants

- Other process industries

Specifications

- Size Range: 8mm to 50 mm

- Socket Weld End: ANSI B: 16.11

- Screwed End ( BSP/BSPT): BS: 21 / IS: 554

- Screwed End (NPT): ANSI B: 2.1

- Butt Weld Ends: ANSI B: 16.25

Features

- Streamlined flow passages to minimise pressure losses and erosion

- Guided piston assuming accurate return to seat ring to achieve leak tightness

- Uniquely designed piston lift check valve, incorporating self-cushioning effect

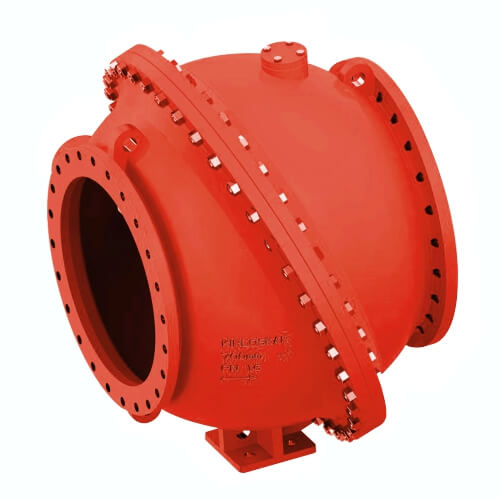

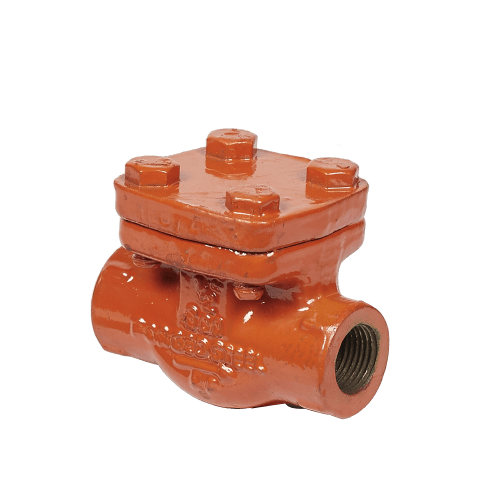

Forged Steel Check Valve

Product Overview

Kirloskar Forged steel FS check valves, widely used by the National Thermal Power Corporation, Nuclear Power Corporation, industrial users and refineries, are designed and manufactured as per BSEN ISO: 15761/ BSEN: 12266-1/ BS 5352 and tested as per BSEN: 12266-1/API -598/BS-5146 standards.

Kirloskar FS check valves are designed for handling very high pressures. Its rigid and sturdy design along with its low pressure characteristicsmake it a very formidable model in the entire product line.

- Refineries and petrochemical industries

- Fertiliser plants

- Thermal power plants

- Other process industries

- Size Range: 8mm to 50 mm

- Socket Weld End: ANSI B: 16.11

- Screwed End ( BSP/BSPT): BS: 21 / IS: 554

- Screwed End (NPT): ANSI B: 2.1

- Butt Weld Ends: ANSI B: 16.25

- Streamlined flow passages to minimise pressure losses and erosion

- Guided piston assuming accurate return to seat ring to achieve leak tightness

- Uniquely designed piston lift check valve, incorporating self-cushioning effect